dannenmann GmbH is a TÜV certified manufacturer

We are certified as a manufacturer of pressure vessels and pipe fittings made of CrNi and non-ferrous metals according to AD2000 HP0 and EN13445-4. Our core competences are forming, welding and processing of cylindrical components up to a unit weight of 10 tons and a maximum diameter of approx. 2,000 mm.

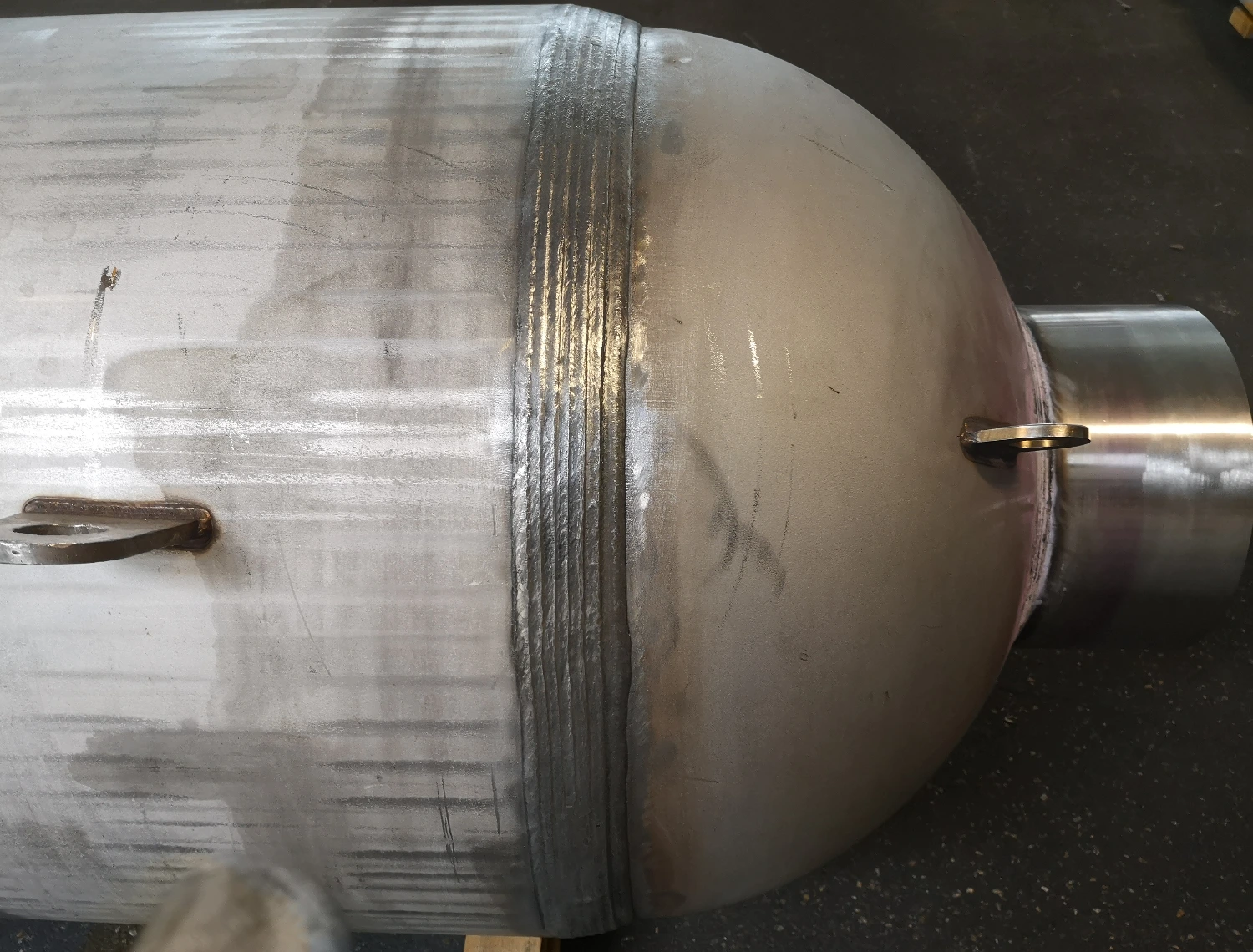

Pressure vessel construction

We manufacture pressureless vessels and pressure vessels made of stainless steels, aluminum alloys and special materials according to your requirements. In addition to manufacturing, we offer development support, design and calculation, including the necessary acceptance by the monitoring organization.

The projects can be carried out according to AD 2000 or EN 13445. Especially in the field of lightweight construction (pressure vessels made of aluminum), as well as in high-pressure and cryogenic technology (double-walled pressure vessels), we have built up a great deal of know-how over many years, with which we are happy to support you.

Pipe fittings

We also manufacture welded elbows and fittings in the diameter range DN200 – DN800 from stainless steels, aluminum and special materials (copper or nickel alloys). In addition to half-shell elbows, this also includes t-pieces, reducers and segmental pipe bends up to a wall thickness of 15 mm.

Our main product, the piping elbow, is manufactured in a half-shell design from sheet metal with two longitudinal seams. This is done according to EN 10253 or your detailed factory standards – gladly also with complex acceptances, or high demands on the welding processes and corrosion resistance. On request, you can also receive complete spools (plant piping) or ready-to-install special components/distributors specifically for your plant.

Contract work

With our highly trained staff and machinery, we can help you with your product, whether it’s a single part or a series. This includes welding work, surface treatment or, for example, forming work on our 300 or 500 ton presses.

Due to our high number of certified welding procedures, both in manual and fully automated welding, we can always use the appropriate procedure for your product. We are equally flexible in adapting our pickling operations (dip pickling or spray pickling) to your product and its requirements.

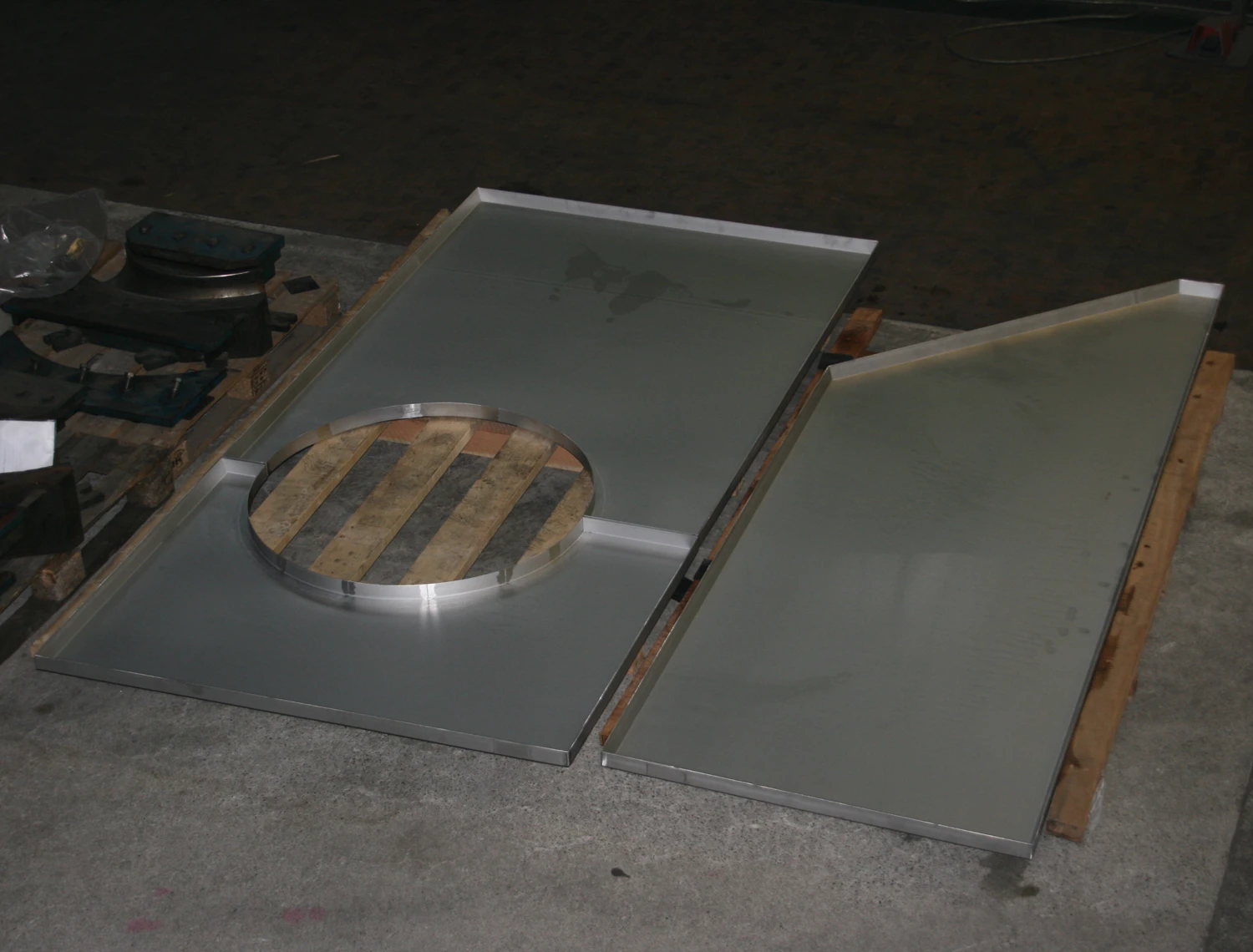

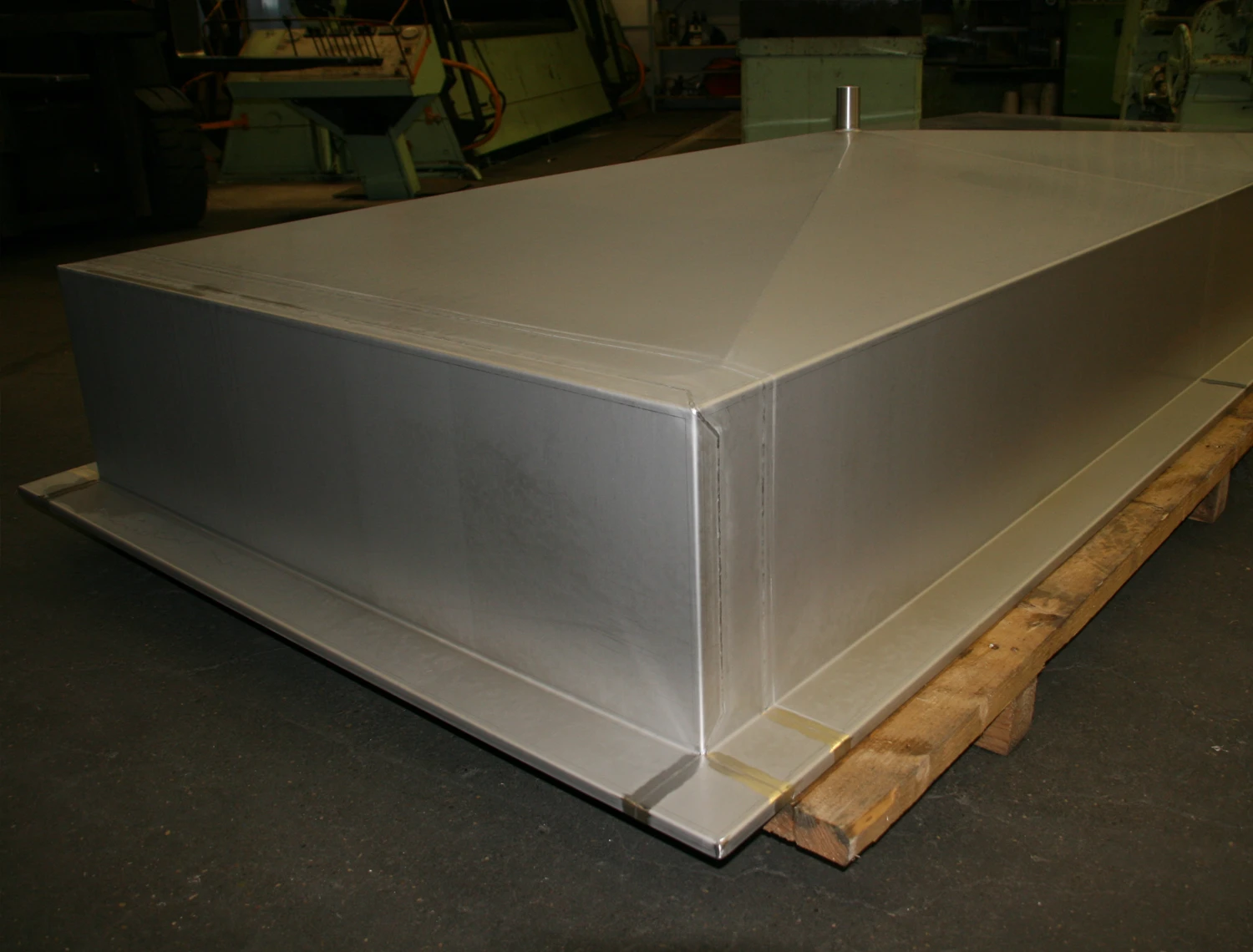

Collection and floor trays

For your machines and applications, we manufacture tightly welded drip pans and floor trays. Certified according to WHG 19 (Water Resources Act), we guarantee that no water-polluting substances seep into the ground.

Made of stainless steel and stained to a matte finish, the tub enhances the overall look of your facility. The cost of this is only minimally more expensive compared to conventional galvanized steel trays due to the reduced wall thickness.

Special designs

We are there for you – even if it should be something special. With our know-how and experience we are able to produce any special construction according to your sketches, drawings or wishes.